History of Banana Fiber Use

Eco-friendly textiles are not a new concept nor are we the first to utilize nature’s bountiful banana fibers for handmade goods. Banana fiber use can be traced back to 13th century Japan in the form of cloth, but its use was limited by production capabilities. The fiber has been used intermittently since then in weaving and rope making, but recently it has been gaining traction in a world very aware of the harmful aspects of fast fashion.

At the turn of the 20th century, inventors Charles M Taylor and Howard Kay Cook sought a way to make handmade paper from other natural fibers stronger than normal wood pulp. They embarked on a journey to develop and patent a more efficient way to extract fibers from flora such as banana trees. They noticed that the natural life cycle of the banana plant created a unique opportunity to have a sustainable source of raw materials rich in fiber.

The Life-cycle of the Banana “Tree”

One of the largest misconceptions about bananas is what happens to the plant after the fruit is harvested. Unlike apple, pear and other varieties of hardwood fruit-bearing trees, banana plants only fruit once in their lifetime and then they naturally die and decay away.

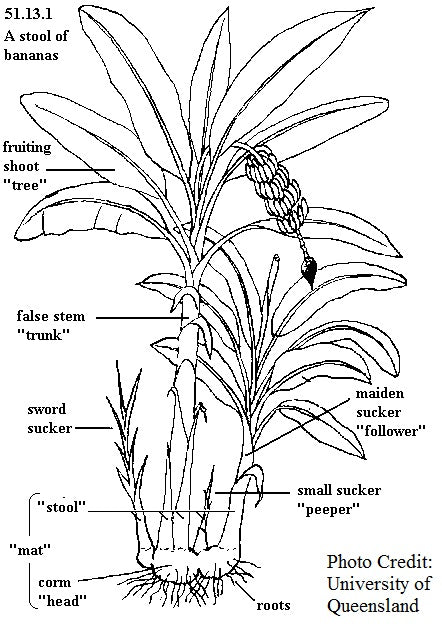

Without going into a full anatomy lesson, bananas are much different than anything we are accustomed to. The stem of the plant is what looks like the trunk of the ‘tree’, but it is actually tightly packed leaf sheaths that overlap as it grows. The most fascinating aspect though has to be the creeping underground stem and root system. It allows five or more generations of fruit-bearing banana stems to simultaneously grow at once.

The plant is categorized as a ‘tree-like perennial herb’ because the parent stem dies naturally after it bears the fruit and a new “sucker” takes over as the parent plant. This is sometimes hard to visualize, but this image shows the smaller offshoots already emerging from the soil waiting for their turn to bathe in the sun.

After farmers harvest the fruit, they chop down the parent stem to help facilitate this natural process and encourage growth. Our intuitive inventors Taylor and Cook noticed that several banana plantations were sitting on a gold mine of fibers otherwise considered waste material from the banana fruit harvest. A world caught up in an industrial revolution was not ready for a slower source of handmade paper, yet...

Humanity’s Relationship with Bananas

The life-cycle of the banana plant takes about 2 years, but it fills an important role as a non-seasonal source of nutrition in many diets around the world. Global consumption of banana fruit has rapidly outpaced the usage of banana fibers in industrial textile production. Worldwide and on average one person consumes 11.9 kgs (26 pounds) of bananas per year as of 2013. With the Earth’s population doubling to over 7 billion people in the last 50 years alone, that’s a lot of unused natural fiber.

Bananas are deeply rooted in pop culture, here's a list of entertaining banana memes to enjoy if you have nothing better to do today.

Properties of banana fiber

As our esteemed inventors pointed out, there are many desirable characteristics of the banana fiber that make it preferable to other textiles beyond the potential supply from our love for the sweet fruit:

While this list does not exhaust the positive benefits of banana fiber, it does provide evidence for increased adoption of banana fiber products.

Slowing down Fast Fashion

With exponentially growing populations and fashion trends coming and going faster than ever, we are beginning to realize the effects of our industrial explosion from the past 100 years. Fashion is now the world’s second leading cause of pollution trailing only oil.

While cotton was gaining popularity as a cheap textile for centuries, banana fiber usage was all but forgotten. At the current scale of manufacturing, the unnatural process used to make clothing from cotton is causing landfills to overflow.

After being treated with chemicals, the cotton no longer continues to decompose as it would naturally. In many places around the world, leather manufacturing also continues to poison environments and the humans that work in the factories. This remains true for many massively produced textiles in modern society.

Environmental champions have shown that sustainable manufacturing practices and processes can help reduce the negative impacts of global consumerism. This now serves as a demand driver for products and companies that leave a smaller carbon footprint.

Socially aware consumers are getting behind social impact companies like never before. For centuries there has been an overwhelming supply of banana fiber material ready for handmade paper making, and now the demand is rising.

Corporations are Going Green Too

In addition to the growing base of customers wanting truly natural processes, many companies have developed eco-initiatives to further sustainability goals. These commitments have come to life in many ways such as reducing their overall energy consumption or adopting a zero waste policy such as Disney’s.

Corporations that plan early for their green initiatives tend to benefit the most from cost savings over time and a greatly improved public image. Many states and federal incentives and rebates exist to help achieve societal environmental goals. Other companies benefit from increased business opportunities if they meet certain standards required to bid on government, commercial and nonprofit contracts.

Help your company can go green by carefully selecting suppliers and vendors for holiday and corporate gifts like these business card holders.

Modern Uses

The uses for banana fiber have not so much changed over time, but the processing has evolved and improved enough to make it commercially desirable. The fibers can be mad into cloth, mats, woven materials, and handmade papers.

With the improvements in extraction and turning the fiber into a pulp, handmade paper stands out as one of the biggest opportunities for banana fiber. The thickness of the paper can be adjusted to achieve the desired texture and to make it suitable for a finished product.

Thick papers can be made to achieve a card stock feeling that is suitable for business cards and greeting cards or thin enough for tissue paper. Papermaking artisans have also experimented with mixing various fibers including recycled paper pulp, pineapple and sakau to achieve a wide variety of papers.

Our primary use with our handmade banana fiber paper is to make vegan and eco-friendly paper wallets. Our Kickstarter in March 2017 helped raise $25,000 to invest in more equipment and pay local workers a fair wage. Our product design phase puts prototypes through rigorous testing so that we make a wallet that’s as beautiful as it is practical.

Wrapping up

Although banana fiber has countless uses, it is not a straight replacement for leather. The handmade paper is great for certain finished products like our paper wallets, but we won't be making shoes with it anytime soon.

Additional information on banana fiber extraction and handmade paper processes is readily available online, but we do not currently have additional material on the subject.

I’m interested in setting up a plant for hand made paper in Hyderabad… Request you to provide info on machinery n training on how to make handmade paper.

Hello, this information and product is very amazing !

Thanks, for providing this useful information. If you want any query about handmade paper visit my site.

Good work, kudos! Keep it up please!!

I wish we can replicate your factory here in Nigeria.

Do you have any arrangement to accommodate that yet?

Thanks.

Interested to know more about technology.this can help to improve environment ….

your company was a great resource for my research paper on how banana plants can be used to save our planet!! THANK you from a eco friendly person!! You are doing amazing things!! the U.S.A should jump on board!!

This is amazing. Am interested to know more about this technology.

How do I get trained on the production of paper, textile and other products.

I am a farmer and own more than 50,000 banana/ plantain suckers.

I want to learn how to make more out of what I have.

Thanks and regards.

Hello

We are going to establish a banana paper production plant in Oman.

Please send me more information.

Regards

This is an amazing venture- creative and sustainable. Very impressive and quality product

Comments will be approved before showing up.

Susan Justus

December 15, 2020

During the Covid Quarantine, I have become fascinated with the banana trees in my backyard! Previously, I had made papers from banana fibers at the Penland School of Craft in North Carolina and was hooked! But given the time to observe the cycle of this plant I was amazed at the myriad and unusual flowers, seeds, pods, fibers, root systems this plant produces. I watched the transformation of the seed pod for weeks – including the bee pollination. The hollowed out roots are home to toads. This plant does everything!!! Thank you for all the information. I bought the large Plumeria pouch – it reminds me of my honeymoon 26 years ago – my husband teased me for singing the “Plumeria song” whenever I would see one:). I still over winter a few here in Dallas, TX. Good luck with your business!